There is an increasing trend for structural engineers to limit their role to the design of key structural members (typically beams and columns) and not other structural aspects. This can be concerning, as it leaves architects to ensure they are aware of those aspects and incorporate them into the design.

One such consideration is that materials such as brick, block and stone are susceptible to changes of dimension over time due to various factors, including:

a) Moisture movement: moisture absorption and evaporation can lead to swelling and shrinkage in masonry

b) Foundation settlement: over time, foundations may settle, causing stresses that can lead to cracking in masonry

c) Dissimilar materials: in certain instances different masonry materials may be combined within the same elevations. For example, clay bricks may be used up to damp proof course level and concrete bricks above. This can create a slip plane on the line of the DPC and allow movement to occur.

d) Changes in wall thickness or height: a movement joint should be placed where there is a change in wall thickness or height to accommodate different expansion rates.

However, the most common issue is thermal movement when temperature changes cause materials to expand and contract. Movement joints, also known as expansion, contraction or control joints, are placed in masonry walls to accommodate the natural expansion and contraction of building materials. Typical distances between joints are set out below, but check with the manufacturer.

Advertisement

Generally, internal walls will be least susceptible to movement, while external south-facing walls, particularly those built of dark coloured bricks, are most susceptible.

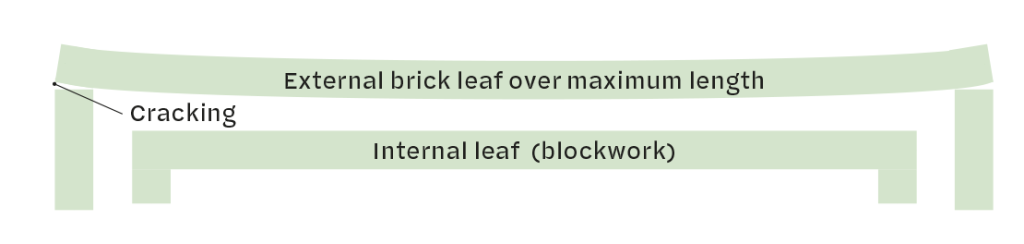

The effect of thermal movement in a south-facing wall will often result in forces that tend to push the corners outward, and cause cracking at the corners.

The effect increases with length, so when the wall length exceeds the maximum length between joints, this needs to be mitigated by subdividing the wall into shorter lengths, ideally by providing the joints close to the corners, rather than centrally in the wall. However, the joints should not be located too close to the corners, as this will weaken the buttressing effect of the flank wall, so typically avoid placing them within 550mm of the internal corner.

It is important that the joints are vertically continuous, so also avoid placing them where they would be interrupted by the line of doors or windows.

The required width of the joint can be calculated as follows: 1/3rd of the distance between joints plus the distance – but measured in millimetres, not metres. So, if you have 12m between joints, then the joint width should be 1/3rd of 12m/1,000 – ie 4mm plus 12mm; 4+12 gives you the 16mm width required for the joint. The material for filling the joints should be easily compressible, but also allow for expansion to return when the wall cools down. Cellular polyurethane, cellular polyethylene or foam rubbers are typically used.

Advertisement

To ensure that the joint doesn’t fail in cavity wall construction, wall ties should be closed up to a maximum of 300mm vertically and 225mm horizontally from the vertical edges of the movement joints to maintain the structural continuity and stability of the wall. Lastly, to prevent water penetration the movement joints should be properly sealed and protected.

Further guidance can be found in PD 6697: 2010 Recommendations for the design of masonry structures to BS EN 1996-1-1 and BS EN 1996-2, as well as manufacturers’ brochures and websites.

Geoff Wilkinson is managing director of approved inspectors Wilkinson Construction Consultants

The Architects’ Journal Architecture News & Buildings

The Architects’ Journal Architecture News & Buildings

Leave a comment

or a new account to join the discussion.